good working coal mill Buy Quality good working coal

good working coal mill, Find Quality good working coal mill and Buy good working coal mill from Reliable Global good working coal mill Suppliers from mobile site on

WhatsApp)

WhatsApp)

good working coal mill, Find Quality good working coal mill and Buy good working coal mill from Reliable Global good working coal mill Suppliers from mobile site on

Grinder Coal Mill Working; Product Reviews. working principle of grinder mill pulverizing mill working principle. A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser works on the

starting coal grinding mill. Coal mill hot air inlet temperatures should never be more than 600 #176; F and the outlet temperature should not exceed 200#176;F on Raymond coal mills If the flow of raw coal to the coal mill is interrupted for any reason for example plugging failure of the coal feeder etc the outlet temperature of the coal mill can quickly climb to dangerous levels

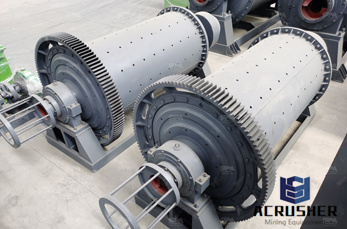

The ball and tube mills are lowspeed machines that grind the coal with steel balls in a rotating horizontal cylinder. Due to its shape, it is called a tube mill and due to use of grinding balls for crushing, it is called a ball mill, or both terms as a ball tube mill. These mills are also designated as an example size, BBD4772,

The Coal Mill Grinder Rotating Table Torque Minery machinery, wholesale various high quality minery machinery products from global minery machinery suppliers and minery machinery factory,importer,exporter at menu menu get the. Rotary kiln Read More. Cement mill Read More. Raw material mill Read More. Coal mill Read More.

Cage mills are mechanical impact machines that crush, grind, or pulverize a variety of materials to specified degrees of fineness. They can be configured in two, four, and six row designs depending on the specific application needs, and are commonly used to pulverize industrial materials including coal and agricultural limestone.

In the condition of raw coals moisture is less than 15%, grinder mill could grind the coal to 200 mesh, drying process could be canceled and energy will be saved. Drying ability could be got from two aspects, when machine working, grinding process will produce heat, meanwhile, hot air would come into machinery from ventilation opening at the bottom of machine, and drying speed will

WORKING PRINCIPLE. The motor drives the grinding table through decelerator. The materials fall down the center of grinding table from feed opening. At the same time, hot air comes into the mill from the air inlet. Due to the centrifugal force, materials move to the edge of the grinding table. The materials are pulverized by the roller when by pass

Metallurgical ContentHammer Mill Working PrincipleCapacity of Hammer Mill CrushersHammermill Grinder discharge product size distributionBasic Hammer Mill Operational ConceptsJeffrey Swing Hammermill PulverizerHammer Mill Capacity The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone. Thus far

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel balls.

Pepper grinders need regular maintenance to keep them working at their best. Explore possible problems with your grinder by taking it apart and investigating which part or parts need to be replaced or fixed. While you have it disassembled, clean all the working parts and complete the simple repair

Clean the mill and grinding mechanisms with a small dry brush. Wipe the body of the mill with rubbing alcohol. Air dry all parts for at least 24 hours. Add dry rock or sea salt to the salt mill. Include a few grains of rice to absorb any moisture. Lubricate the threaded part of the mill, lightly using cooking oil and fingers.

Coal mill, which is also known as coal grinding mill or coal milling machine, is used to pulverize and dry coal before it is blown into the power plant furnace in the coalfired power plants. Whether the new or second hand coal mill, it has the same working principle.

Working Principle. The main motor drives the disc through the speed reducer to rotate, and the hot air from the air inlet into the vertical grinding mill body, material from the feeding port to the central disc and under the action of centrifugal force from the disc center to the edge of uniform movement, after roller grinding area disc, by grinding roller compaction, bulk material directly

WORKING PRINCIPLE. The motor drives the grinding table through decelerator. The materials fall down the center of grinding table from feed opening. At the same time, hot air comes into the mill from the air inlet. Due to the centrifugal force, materials move to the edge of the grinding table.

WhatsApp)

WhatsApp)