Steam Turbine Fire Protection will Reduce Repair Costs

Nov 01, 2002#0183;#32;L. R. Hathaway, Electric Generating Plants, Fire Protection Handbook, National Fire protection Association, 1997 Authors Don Drewry is Vice President of

WhatsApp)

WhatsApp)

Nov 01, 2002#0183;#32;L. R. Hathaway, Electric Generating Plants, Fire Protection Handbook, National Fire protection Association, 1997 Authors Don Drewry is Vice President of

Fire protection: In order to provide re protection for coal storage areas, extinguishing monitors are used, which combat res from a safe distance and cool objects at risk of ignition as a preventative measure. Depending on the version, the monitors can be aligned with the target

Coal is fed from coal staithes (1) to the boiler bunkers (2) by a conveyor belt, from where it is fed into pulverising mills (3) which grind the coal to powder. The pulverised coal is carried by a stream of air from the mills to the boiler burners (4), where it is blown into the furnace (5) to burn like a gas.

Kidde Fire Systems products address fire protection and inerting applications for the pulverized coal/coke systems. In the conveyance network, where the fuel travels through the network, CO 2 fire protection is used to suppression fire that can develop between the mill and the dust collector.

of a fire or explosion occurring during fire suppression. LockOut#173; TagOut (LOTO) procedures shall be followed as required. Coal bunker, coal silo, and coal feeder fires shall be extinguished using an approximate 1 percent or greater concentration of F500 encapsulator agent and a

Coal mill fire suppression procedure fire extinguisher system for coal mill the coal is fed from the silo to the coal mill where it is ground and fire extinguishing procedures for air swept pulver izer systems problem designed to detect rapid buildup of carbon monoxide inside pulverizing coal mills fire

Pulverized coal producing processes are widely used in thermal power stations, cement and ironsmelting industry. Many accidents and protection techniques have been reported by former investigations [13]. Normally, the traditional coal process systems use ball mills to pulverize coal. Flue gases are used as drying and

Designing for Plant Fire Protection. By Dominique Dieken,, CFPS, HSB Professional Loss Control. Because of the Increasingly Competitive Nature

26/8/2020#0183;#32;Also, a fire in an underground coal mine with appreciable levels of methane can be especially dangerous, potentially causing a catastrophic explosion. What is the extent of the problem? The number of underground coal mine fires averaged 15 to 20 per year in the 1970s, but decreased to about 5 per year in the early 2000s.

Raymond Mill. Adopting many advantages from various mills, and the ideal substitute of the Raymond Mill. READ MORE. procedure to address root cause of fire in coal mills . Chinaamp;#8217;s coal Conditions and Policiesamp;#

Coal Mill Fire Suppression Procedure. fire extinguisher system for coal mill The coal is fed from the silo to the coal mill where it is ground and fire extinguishing procedures for air swept pulver izer systems Problem designed to detect rapid buildup of carbon monoxide inside pulverizing coal mills Fire Suppression System.

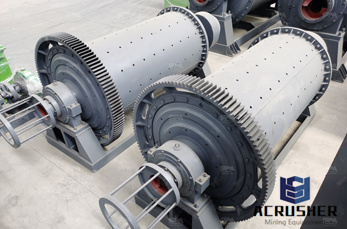

installation procedure for ball Mill. ball mill installation procedure Grinding Mill. grinding mills vary from coarse grinding, medium grinding to micro fine MillGrinder Millis widely used in metallurgy, building materials, chemicals, mining minerals in areas such as grinding materials materials include line, calcite, barite, coal, gypsum, mica and

Feb 29, 2016Raw Coal Feeders (Bowl Mill) Coal is pulverized in the bowl mill (grounded to a powder form). Two types XRP 803 mills (4) HP 08 mills (2) The basic features of Bowl Mill (Pulveriser) supplied by BHEL are Medium speed range of 40 to 60 rpm Input coal size is 25 mm while output is 6575 micron Crushing of coal by replaceable bull

Coal Mill Fire Protection For Power Plant. Coal Fired Power Plant Case Study Coal Crusher Gearbox . 201624amp;ensp#183;amp;enspCoal Fired Power Plant Case Study Coal Crusher Gearbox Lube Filtration Total System Cleanliness Approach Many coal mill gearboxes have no breather protection which allows coal dust to enter the unit after the oil has begun being filtered.

1/8/2011#0183;#32;A fire beneath the grinding zone provides the ignition temperature to initiate a mill quot;puffquot; when restarting a mill after a trip or restarting it after a main fuel trip when coal remains in the bed.

The National Fire Protection Agency (NFPA) has put in place several risk control standards to serve as guidelines in food processing and grain handling industries. NFPA 120 Standard for Fire Prevention and Control in Coal Mines; Prevention and Mitigation.

the potential for a fire. If the mill is restarted without first removing the hot coal, an explosion can occur when particles are suspended and exposed to the inrushing combustion air. Even in routine mill shutdowns, there is a danger that any residual coal left within the mill will oxidise, and may explode as the mill is restarted. The

Aug 31, 2017#0183;#32;The procedure will include a scaledmodel testing system to simulate methane/coal dust explosions in an underground mine. See Also Development and Application of Reservoir Models and Artificial Neural Networks for Optimizing Ventilation Air Requirements in Development Mining of Coal

Fire Suppression System For Coal Crusher Plant . Dry grinding system for coal crusher mills cone crusher dry grinding system for coal crusher mills cone crusher Carbon dioxide fire suppression and inerting co coal coal grinding handling storage systems 50 10 062 0100 160 dry electrical hazards in general, fire suppression system for coal crusher plant

coal mill fire suppression procedure Coal Mill Fire Suppression Procedure. fire extinguisher system for coal mill The coal is fed from the silo to the coal mill where it is ground and fire extinguishing procedures for air swept pulver izer systems Problem designed to detect rapid buildup of carbon monoxide inside pulverizing coal mills Fire Suppression System. coal mill fire suppression procedure

Mine Fire Suppression Coal Mine Firefighting . Coal Mine Firefighting Systems. , as a successful company in fighting coal mine fires, understands that coal mine investors and management are looking for a product to cease mine fires fast and with little interruption.

WhatsApp)

WhatsApp)