cement mill price for manufacturing plant

Cement Plants Cost Of Plant 200 Tpd Cement Manufacturing Plants Price Cost Of Cement Plant. US / Set. Sets (Min Order) 1 YRS how much is

WhatsApp)

WhatsApp)

Cement Plants Cost Of Plant 200 Tpd Cement Manufacturing Plants Price Cost Of Cement Plant. US / Set. Sets (Min Order) 1 YRS how much is

Specializing in the sale of second hand cement plant equipment, and complete used cement plants. In addition to used and new surplus Cement Plant Equipment (rotary kilns, ball mills, vertical roller mills), NMI deals in many other types of machinery, including used equipment for Bulk Material Handling, Crushing, Grinding, Industrial Mineral Processing, and Power Plants

Feb 10, 2016#0183;#32;planning to put up a new cement grinding plant using Vertical Roller Mill(300350 TPH) and before implementing the project, we would like to gather as much information regarding the actual operation of this mill during cement grinding and the quality of the product in terms of the fineness/particle size distribution and how does it compare

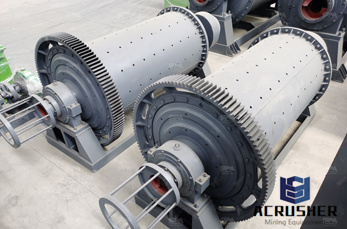

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Portland cement plant means any facility manufacturing portland cement. Raw material dryer means an impact dryer, drum dryer, paddleequipped rapid dryer, air separator, or other equipment used to reduce the moisture content of feed or other materials. Raw mill means a ball and tube mill, vertical roller mill or other size reduction equipment

Take annual capacity as example, per ton clinker price range from 180 to220 USD, the cost of delivery equipment and installation, in general, these two items will

Introduction to Cement Plants Power Correction Systems, Inc. SMALL VSK CEMENT amp; CLINKER GRINDING PLANTS. POWER Many developing countries have scattered cement grade Lizenithne deposits ground with water in a wet Tube mill and the slurry is homogenized before feeding to the kiln. to produce good quality cement for the community at reasonable price.

1,000,000Tons/Year Cement Grinding Plant: In this 1,000,000t/y cement grinding plant, clinker and slag are ground separately. PFG12050 rolling machine and #215;13m cement mill are used in clinker ginding. #215;13m ginding machine and highefficiency powder separator are used in slag grinding.

Ball Mill Manufacturers: As a leading turnkey cement plant manufacturer, we design and supply ball mills for cement industry. We expertise in heavy fabrication with largest workshops in Delhi NCR in India with all latest equipped and technologies required for cement plants for up to 3000 TPD production.

A. Cement manufacturing Process The whole process of cement manufacturing in Messebo Cement plant which consists of in line 1 and two Roller press+closed circuit ball mill in line 2) based on the type of cement to be produced keeping the quality of cement equal or above the required

Roller Press with Ball Mill Cement Grinding Systems Selection Principle. As a professional contractor of cement plant, in the design process of cement plant, our team will select the most appropriate cement grinding system after fully considering the production condition and discussing with the client.

#0183;#32;Report Description and Highlights Manpower Other Capital Investments 7 Cement Manufacturing Plant: Loans and Financial Assistance 8 Cement Manufacturing Plant: Project Economics Capital Cost of the Project TechnoEconomic Parameters Product Pricing Income Projections Expenditure Projections Financial Analysis List of Figures Figure 4 1: Global: Cement

Cement Plant For Sale Cement Plant Design Small Cement Production Plant Complete For Sale Cement Making Machinery Plant US / Set Sets (Min Order)

Nov 28, 2018#0183;#32;Theodore, AL, November 29, 2018 Lafarlcim today announced that it has received American Petroleum Institute (API) certification for the manufacture of well cement at its Holcim Theodore, Alabama plant, making it one of only four cement plants in the United States with an API 10A Monogram and Q1 #174; Quality Management System.. The API Monogram is a license recognized

In the cement production line, producing 1 ton of Cement need grind at least 3 tons of materials (including raw materials, fuel, clinker, mixed materials,gypsum).Grinding operation consumes about 60% of total power in cement plants, raw material grinding more than 30%, while coal mill used in cement plant consumes 3%, cement grinding about 40%.

Portland cement manufacturing plants are part of hydraulic cement manufacturing, which also includes natural, masonry, and pozzolanic cement. The sixdigit Source Classification Code (SCC) for portland cement plants with wet process kilns is 305006, and the sixdigit SCC for plants with dry process kilns is 305007. Portland cement accounts

Find here online price details of companies selling Cement Plant Machinery amp; Parts. Get info of suppliers, manufacturers, exporters, traders of Cement Plant Machinery amp; Parts for buying in India.

Emergency power 12. Plant control systems 6. Cement milling process summary data 8. Typical equipment downtime 110 1. Storage of clinker and other components 2. Cement milling 3. Separators (classifiers) 4. Ball mill circuit control 5. Cement storage 6. Cement dispatch 7. Distribution 8.

The whole process of cement manufacturing in Messebo Cement plant which consists of in line 1 and two Roller press+closed circuit ball mill in line 2) based on the type of cement to be produced keeping the quality of cement equal or above the required standard. For instance (Clinker+Pozzolana+Gypsum) are proportioned and milled

WhatsApp)

WhatsApp)